Heating Cable System Suppliers

An armored MI heating cable (mineral insulated heating cable) is a solid body made of a metal protection tube, inorganic armored heating cable material insulator (such as magnesium oxide, alumina, etc.), electric heating wire material combination, compacted by mold. It is pressure-resistant, shock-resistant, flexible, energy-saving, high impermeability, radiation resistance, explosion-proof, safe and reliable, easy to install, high mechanical strength, long service life, and other advantages. It is widely used in aerospace, nuclear energy, petroleum, chemical industry, construction, machinery, electric energy, and other industrial sectors and scientific research and teaching fields, in the international application, has been verified for more than forty years.

Technology

Application

Certificate

- UL Certificate -KSOT2.E89693-Heater, Specialty-Assemblies

- UL Certificate -KSOT8.E89693-Heater, Canadian Specialty-Assemblies

- Specification S-311-P-079: Purchase Specification for Thermofoil™ Heaters

- Specification EN60335-1: Standard for the safety of electrical appliances for household and similar appliances. Part 1: General requirements

Related Products

Looking for solutions?

We can provide a complete thermal management solution to solve all your problems in one stop.

About Us

TAISUO Technology was founded in 1992, and is a professional Heating Cable System Suppliers and Heating Cable System Company, A new professional invisible champion enterprise dedicated to the research and development, production, sales and service of thermal management technology. It has been focusing on the industry for 30 years. Taisuo has dozens of utility model and invention patents. The company has professional and rare technical control in the field of temperature and thermal management, such as "heating and cooling, temperature sensing, transmission control, special signal processing" and other multi-dimensional technical challenges, which can be used for auto parts, energy, petroleum, military industry, thermoelectricity , chemical industry, nuclear power, medicine and other industries to solve technical problems of temperature control equipment. We specialize in custom Heating Cable System etc.

As a long-term cooperative supplier, Teso Technology has gradually spread its footprints all over the world and has continuously refreshed its transformation goals in industry segments, becoming a leading company in the temperature and thermal management segment.

Patent

-

Ultra-long high-temperature and high-pressure multi-point oil well temperature sensor and its preparation method

Ultra-long high-temperature and high-pressure multi-point oil well temperature sensor and its preparation method -

An integrated oil well heating cable with continuous monitoring

An integrated oil well heating cable with continuous monitoring -

An armored cable integrating heating and movable armored thermocouples

An armored cable integrating heating and movable armored thermocouples -

A high temperature resistant integrated underground heating cable

A high temperature resistant integrated underground heating cable -

A heating cable with variable power in the length direction and a three-phase integrated heating cable

A heating cable with variable power in the length direction and a three-phase integrated heating cable -

Automatic correction device for pipe forming

Automatic correction device for pipe forming -

A multi-point temperature measurement oil well heating cable

A multi-point temperature measurement oil well heating cable -

A multi-point oil well temperature sensor

A multi-point oil well temperature sensor -

A high and low temperature connecting rod for automobile engine temperature sensor

A high and low temperature connecting rod for automobile engine temperature sensor -

A variable diameter armored thermocouple cable

A variable diameter armored thermocouple cable -

A temperature sensor for locomotives

A temperature sensor for locomotives -

A kind of nuclear power peripheral rapid temperature measurement thermocouple

A kind of nuclear power peripheral rapid temperature measurement thermocouple

Industry Certification

-

Zhejiang Province Small and Medium-sized Science and Technology Enterprise Certificate

Zhejiang Province Small and Medium-sized Science and Technology Enterprise Certificate -

Yuyao Engineering Technology Center Approval Document

Yuyao Engineering Technology Center Approval Document -

Teso thyristor voltage regulator control software copyright registration certificate

Teso thyristor voltage regulator control software copyright registration certificate -

Quality management system certification

Quality management system certification -

Certificate of conformity

Certificate of conformity -

Production certification certificates for armored cables, temperature sensors, and heat-resistant pipe midsections

Production certification certificates for armored cables, temperature sensors, and heat-resistant pipe midsections -

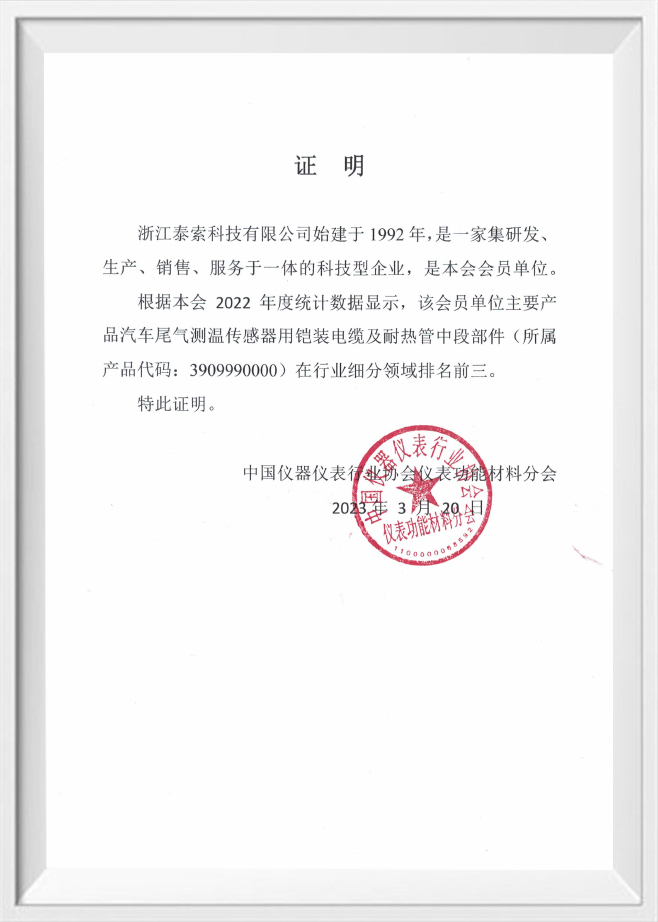

Market share ranking in 2022

Market share ranking in 2022 -

High-tech Enterprise Certificate

High-tech Enterprise Certificate -

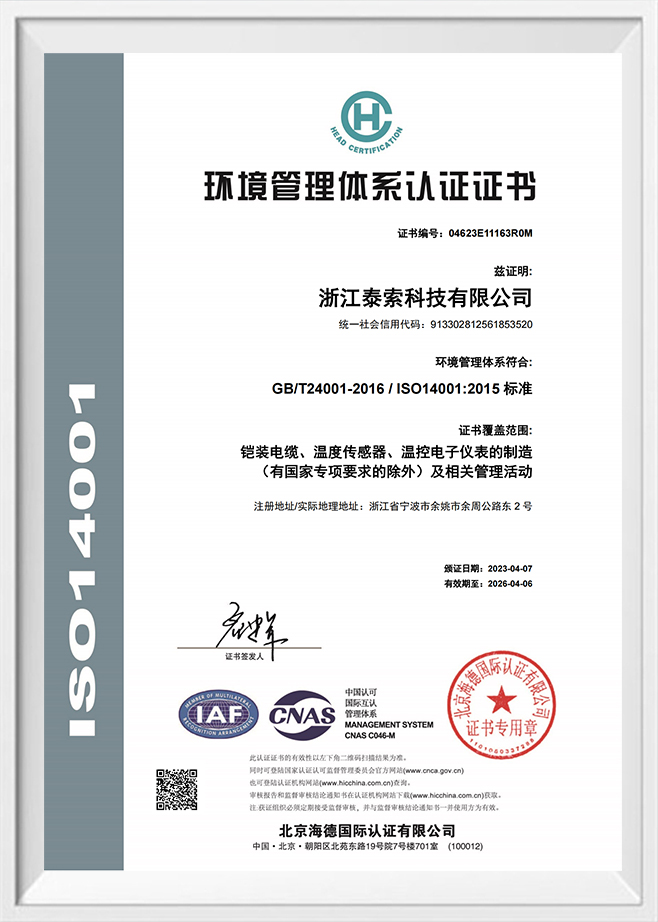

environmental management system certification

environmental management system certification -

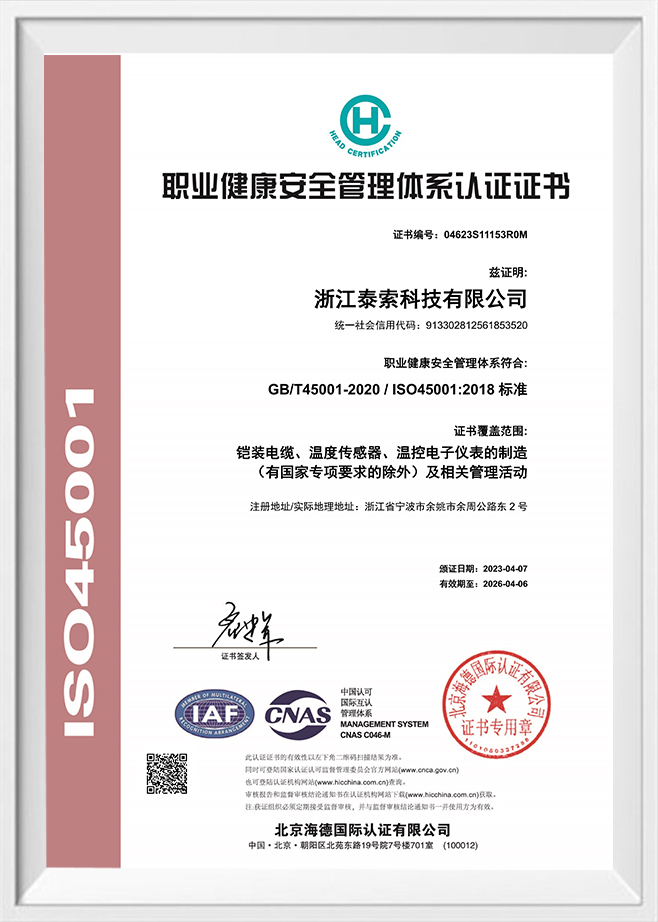

Occupational Health and Safety Management System Certification Certificate

Occupational Health and Safety Management System Certification Certificate -

Carbon fiber composite material testing report

Carbon fiber composite material testing report

News Center

-

News 2025-05-25

1. General maintenance methods for temperature controllersUse dry cloth or soft brush to clean the surface and internal components...

Read more -

News 2025-05-19

1. Common faults and causesUnable to heat -Reason: The heating wire of the Tubular Heater is broken, the wiring is loose or broken...

Read more -

News 2025-05-11

Thermocouple sensor is a key component for temperature measurement based on thermoelectric effect. Its working principle is essent...

Read more -

News 2025-05-02

1. High fire resistance and fire safetyMineral insulated cables are composed of copper conductors, magnesium oxide insulation laye...

Read more

English

English русский

русский 简体中文

简体中文

Ins: tai_suo

Ins: tai_suo